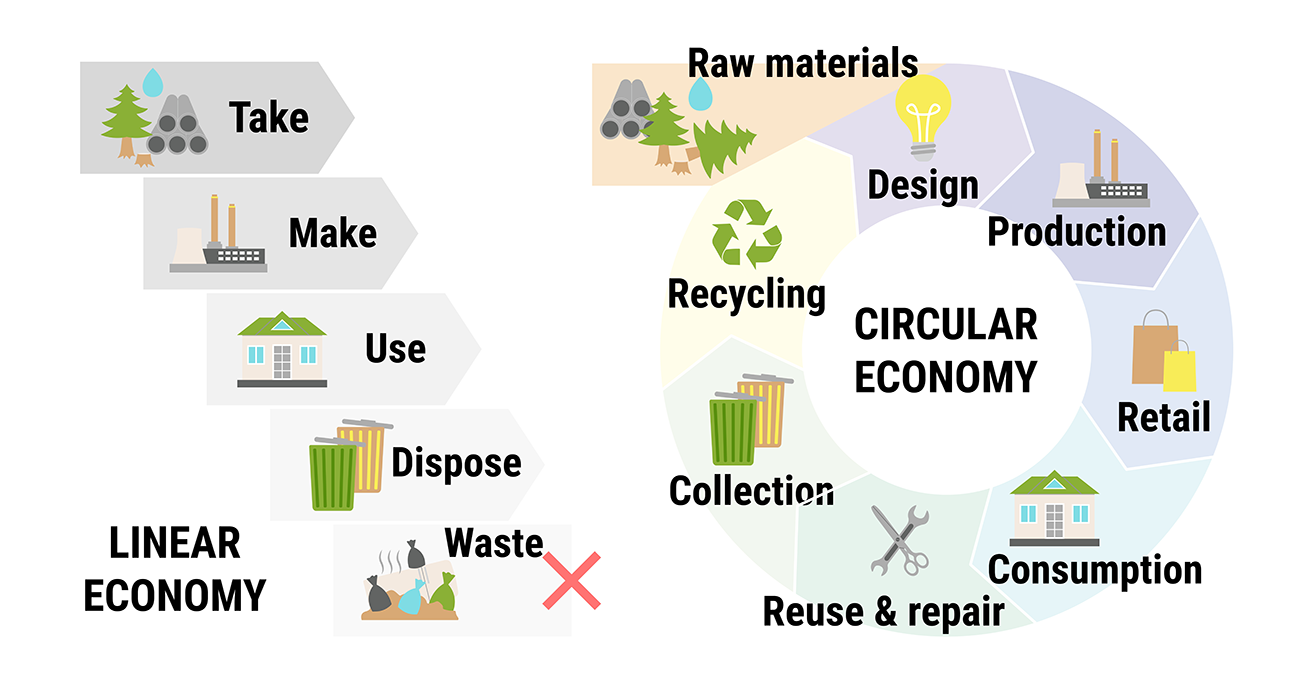

Currently there are two types of material flows that occur in society: linear and a limited amount of reuse and recycling. An aspiration is to have closed loop material flows that underpin a circular economy, by keeping the matter making up materials in use as products longer and maximizing matter’s regeneration into high-value products at the product’s end of life.

The basic elements of a circular economy are to: prioritize regenerative resources, design for the future, preserve and extend what’s already made, rethink the business models, use waste as a resource, incorporate digital technology, and collaborate to create joint value. This is a complex challenge that demands a multidisciplinary approach combining fundamental science and engineering to create the necessary materials and technologies to underpin circular systems, but also policy and economics to enable society to make the transition to a circular economy.

RBI’s Circular Materials focuses on polymer-based materials, including composites, with the ultimate goal of identifying materials and/or processes that can minimize the use of non-sustainable resources (fossil fuels) as feedstocks or energy sources. That includes:

- Recycling at the molecular level, for example molecular restoration or regeneration, which is very common in nature, through such processes as mechano-catalysis, separations, electro-catalysis, etc.;

- Replacing the functionality provided by petroleum-based polymers with polymers from biomass. Optimized biomass processing to synthesize common monomeric building blocks and/or new ones through approaches as redesign of products, processes, policies, economies and workforce education.

- Reducing the energy input and other resources i.e., water, materials and transportation costs, minimizing waste streams e.t.c., in current manufacturing processes of products made using petroleum-based feedstocks.